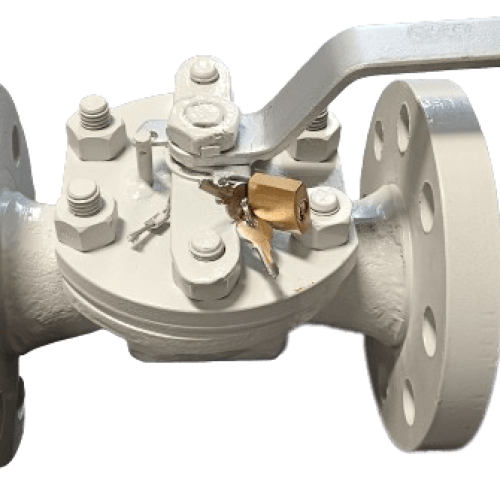

Top Entry Ball Valve

Top Entry Ball Valve

Kent Top Entry Trunnion Mounted Ball Valve is an advanced design of Top Entry ball valve, manufactured in a wide range of diameters and pressure classes, and is used in pipelines and critical process applications. These valves are fully in-line field repairable, thus eliminating long down times. The bolted construction allows disassembly on-site for inspection and possible repair. Removal of the bolted cover from the valve body allows access to the ball and seats, which can be removed with special maintenance tools. The valves have standard design features such as a built-in cavity relief mechanism, anti-static, emergency sealant injection, drain and vent, and intrinsic double block and bleed facility. Other standard features of these top-entry ball valves are as below. • Full Internal weld overlay or weld overlay on seat pocket area and body cavity can be provided with in-house cladding facility. • Metal seated valves seat and ball surface are either Tungsten carbide, Chromium carbide coated or Stellite Coated with in-house HVOF coating technology. Fully welded ball valves are also offered, eliminating the potential flange leak path and increasing resistance to pipeline pressure and stress with an in-house welding facility. • Stem extension can be provided depending upon the customer’s requirements. • Seat construction with Single piston effect and double piston effect can be provided. • All valves are fire safe tested as per API 607 / API 6FA.

Product Standards

Product Details

Special Features

| Specifications | Details |

| Design Standard | API 6D, API 608 |

| Pressure/Temperature Chart | ASME B16.34 |

| Face to face Dimension | ASME B16.10 |

| Testing Standard | API 598 / API6D / BS EN 12266-1 |

| Flange Details | ASME B16.5 UP TO 24″

ASME B16.47 26″ and Above DIN / BS / IS / JIS |

| Butt-Weld End Details | ASME B16.25 |

| Size Range | 2″ – 24″ (DN50 – DN600) |

| ASME Class | Class 150 to 2500 |

| Bore Type | Full Bore and Reduced Bore |

| Materials | A105 / LF2 / LF3 / F316 / F304 / F316L / F51 / F55 / F6a / WCB / LCB / LCC / CF8M / CF8 / CF3M / 4A / 6A / Inconel |

| Trims | F6a / F316 / F304 / F316L / F51 / F55 / Inconel / 17.4 PHF6a / F316 / F304 / F316L / F51 / F55 / Inconel / 17.4 PH |

| Seat | Soft / Metal |

| Ends | Flange ends, Butt-weld End |

| Operation | Manual, Pneumatic, Electric |

- Top Entry Trunnion Mounted Ball Valve design complies to API 6D, API 608.

- Accessibility to all the valve internals from the top.

- In-line valve maintenance, without disassembling the valve from the pipeline.

- Reduces maintenance downtime.

- Body cover joint not exposed to pipeline stresses.

- Fire-safe to ISO 10497 and API 607 and API 6FA.

- Fugitive emissions – Soft and Metal seated valves complies to ISO 15848-1, Class AH and BH.

- Double block and bleed (DBB) feature – Valves are designed and tested for automatic cavity relief.

- Anti-blowout stem design.

- Coil springs used for consistent seat loading and lower operating torque.

- Lip seals provided for low temperature services.

- Where tight shut off is required, Double piston effect (DPE) seats provided for redundancy in sealing.

- Cavity Pressure Relief mechanism.

- Stem seal configurations to API 622.

- Mirror-finished solid stainless ball.

- Antistatic feature.

- Actuator-mounting flange conforms to ISO 5211.

- Single, two and three piece constructions.

- Full-bore and regular-bore designs.

- Soft and metal-seated.

- Flanged ends, Butt Weld Ends, Socket-weld Ends and Screwed Ends.

Catalogues

No Catalogue found